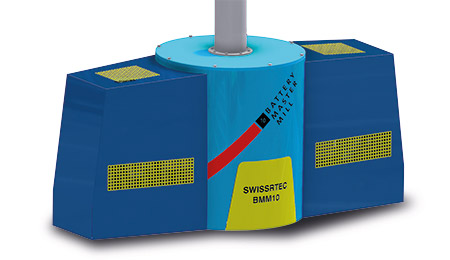

SWISSRTEC BATTERY MASTER MILL

Li-Ion Batteries :: Anode and Cathode Foils with Black Mass :: Production Waste

The BATTERY MASTER MILL is an impact mill specially designed for the post-treatment and ball shaping of anode and cathode material from Li-ion battery recycling. The input material is fed into the mill from the top. During the process, high impact forces act on the material, the adhering black mass detaches in the process, and the anode and cathode material is simultaneously crushed and ball shaped. The material is pneumatically conveyed through the mill. The subsequent separation steps enable the individual fractions to achieve high quality output.

Product Advantages

- Gentle liberation of the black mass

- Ball shaping of anode and cathode material

- Bidirectional rotor

- Maintenance friendly

- Fast tooling replacement and multiple use

- Energy optimized drive

- Solid, reliable machine design